stone floor polishing machine

2018-07-24 20:32:16 By:Utand Stone Machinery (2654)

stone floor polishing machine

In order to ensure the quality of the workpiece, stone floor polishing machine will be edited and disposed in advance, so that when polishing the shape of the workpiece, it can ensure that its dimension precision is higher, and the polishing quality is better, thus improving the polishing quality.

The normal operation of the stone floor polishing machine can not be separated from some key parts. The added part includes it. In the case of sufficient pressure, the stone floor polishing machine can complete the polishing operation smoothly. How is the increase device that matches the cutter polishing machine? Let us teach a professional manufacturer.

In fact, it is very simple, there are special turbocharger used in the market, and the stone floor polishing machine is also the device. At present, domestic and imported turbochargers are common in the market, but the difference between them is very obvious, because we start late in water jet technology, so the corresponding technical level There must be no advanced foreign countries, even if the domestic supercharger and imported products made of the same materials are still very different.

But the reason why the domestic added device can also be welcomed by the majority of users, mainly because of its low cost characteristics, as long as the reasonable arrangement of domestic turbocharging can also meet the pressure demand, generally speaking, domestic turbochargers are mostly used under the pressure demand below 2500bar, such as ceramic tiles, stone, glass and other materials polishing, once. Domestic pressure booster is not up to pressure demand.

Customers reflect that the water knife accessories are often not used as long as they do, and the life of the water knife has not been as long as expected. In the final analysis, it has a great relationship with the metal fatigue problem of the fittings of the water knife, and there are many reasons for the metal fatigue of the water knife accessories. If you want to avoid it, we should find out the specific reasons.

First of all, it is necessary to understand that the so-called metal fatigue is the process of cracking and cracking of the solid metal after a long time repeated force, resulting in the physical properties of the original strength, such as the physical properties of the original strength, and even the process of cracking and cracking. The stress values are not more than the strength limit of the material, even than the elastic limit, when the fittings are repeatedly loaded. It is also likely to be damaged in a low situation.

Every time, the water knife is in the low pressure water after the pressure increases, so that the various parts on the water knife will be subjected to a large load, and then the high pressure water through the high-pressure one-way valve to complete the whole cutting action, as the high-pressure cylinder of the water knife parts into the low pressure state, so all kinds of water knife parts matching. From a high pressure to a low pressure, from expansion to contraction, pressure circulation and repetition, it will be damaged after a period of time.

stone floor polishing machine

Therefore, the service life of the stone floor polishing machine depends on the ultimate strength of the steel material of the water knife, and the size of the surface heat treatment process and the pressure of the water knife. When each cycle pressure level is close to the limit strength of the water knife parts, the parts will be easily damaged.

If you want to extend the service life of the fittings, it is necessary to reduce the pressure, but the reduction of the pressure will slow the cutting speed and reduce the overall economic benefit. It is very contradictory that we can only balance the relationship between the two as much as possible.

When the stone floor polishing machine polishing smaller and thinner objects, it is easy to skid in cutting, because the smaller and more precise cutting body is not good for fixing, and the water knife brick can keep it well, effectively assist the fixed position of the spray head of the water knife, and prevent the cutting precision from the jitter.

In addition, the water knife brick can eliminate the phenomenon of water spattering or water absorbing when the water knife works. Its corrugated groove design can quickly remove the water and debris. Not only that, the water knife brick can complete any material from cardboard to steel plate, granite, ceramics, concrete and so on.

Under the conditions of the software, the NC milling function and the artistic carving can be realized, and the features of high automation and flexibility are shown. With the numerical control system, it can carry out the arbitrary shape processing with any complex shape, and the incision is smooth and the machining precision is high, and there is no need for two processing.

In this case, how is the plane cutting less water cutting machine, when the cutting thickness is less than 2.5 of the material, the production of medium or large cutting head is not high, so it is possible to use small parameter combinations and consider the use of multi head cutting to increase production.

-

Related News:

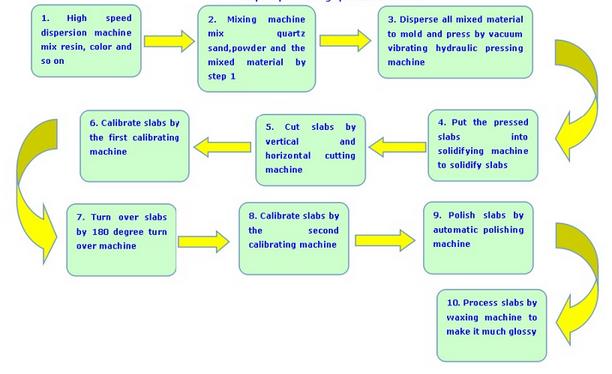

- artificial marble manufacturing process

- Cnc machine for quartz stone

- stone floor polishing machine

- Cnc stone cutting machine for sale

- Hi 2021

- solid surface machine manufacturers

- engineered stone manufacturing process in china

- quartz stone curing oven of introduced

Hi, we intend to sell this website, if you are interested, please contact us:

Email:529733977@qq.com

Address:Huanan industrial park,Foshan City,Guangdong Province.

Contact Us